|

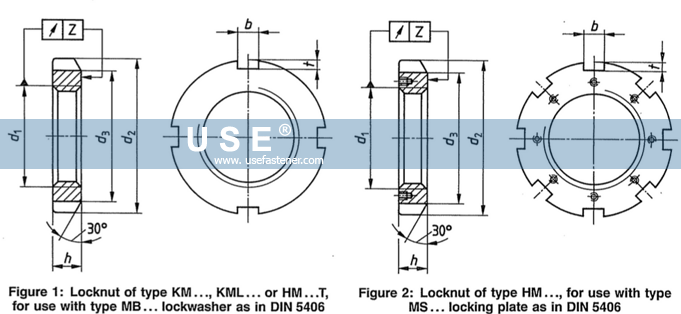

d1

|

d2

n13 |

d3

h13 |

d

h13 |

d

h13 |

t

H17 |

z

|

Symbol

|

Type of suitable DIN 5406 lock washer

|

|

M10x0.75

|

18

|

13.5

|

4

|

3

|

2

|

0.04

|

KM0

|

MB 0

|

|

M12x1

|

22

|

17

|

4

|

3

|

2

|

0.04

|

KM1

|

MB 1

|

|

M15x1

|

25

|

21

|

5

|

4

|

2

|

0.04

|

KM2

|

MB 2

|

|

M17x1

|

28

|

24

|

5

|

4

|

2

|

0.04

|

KM3

|

MB 3

|

|

M20x1

|

32

|

26

|

6

|

4

|

2

|

0.04

|

KM4

|

MB 4

|

|

M24x1.5

|

38

|

32

|

7

|

5

|

2

|

0.04

|

KM5

|

MB 5

|

|

M30x1.5

|

45

|

38

|

7

|

5

|

2

|

0.04

|

KM6

|

MB 6

|

|

M35x1.5

|

52

|

44

|

8

|

5

|

2

|

0.04

|

KM7

|

MB 7

|

|

M40x1.5

|

58

|

50

|

9

|

6

|

2.5

|

0.04

|

KM8

|

MB 8

|

|

M45x1.5

|

65

|

56

|

10

|

6

|

2.5

|

0.04

|

KM9

|

MB 9

|

|

M50x1.5

|

70

|

61

|

11

|

6

|

2.5

|

0.04

|

KM10

|

MB 10

|

|

M55x2

|

75

|

67

|

11

|

7

|

3

|

0.05

|

KM11

|

MB 11

|

|

M60x2

|

80

|

73

|

11

|

7

|

3

|

0.05

|

KM12

|

MB 12

|

|

M65x2

|

85

|

79

|

12

|

7

|

3

|

0.05

|

KM13

|

MB 13

|

|

M70x2

|

92

|

85

|

12

|

8

|

3.5

|

0.05

|

KM14

|

MB 14

|

|

M75x2

|

98

|

90

|

13

|

8

|

3.5

|

0.05

|

KM15

|

MB 15

|

|

M80x2

|

105

|

95

|

15

|

8

|

3.5

|

0.05

|

KM16

|

MB 16

|

|

M85x2

|

110

|

102

|

16

|

8

|

3.5

|

0.05

|

KM17

|

MB 17

|

|

M90x2

|

120

|

108

|

16

|

10

|

4

|

0.05

|

KM18

|

MB 18

|

|

M95x2

|

125

|

113

|

17

|

10

|

4

|

0.05

|

KM19

|

MB 19

|

|

M100x2

|

130

|

120

|

18

|

10

|

4

|

0.05

|

KM20

|

MB 20

|

|

M105x2

|

140

|

126

|

18

|

12

|

5

|

0.05

|

KM21

|

MB 21

|

|

M110x2

|

145

|

133

|

19

|

12

|

5

|

0.05

|

KM22

|

MB 22

|

|

M115x2

|

150

|

137

|

19

|

12

|

5

|

0.05

|

KM23

|

MB 23

|

|

M120x2

|

145

|

135

|

20

|

12

|

5

|

0.05

|

KML24

|

MBL 24

|

|

M120x2

|

155

|

138

|

20

|

12

|

5

|

0.05

|

KM24

|

MB 24

|

|

M125x2

|

160

|

148

|

21

|

12

|

5

|

0.05

|

KM25

|

MB 25

|

|

M130x2

|

155

|

145

|

21

|

12

|

5

|

0.06

|

KML26

|

MBL 26

|

|

M130x2

|

165

|

149

|

21

|

12

|

5

|

0.06

|

KM26

|

MB 26

|

|

M135x2

|

175

|

160

|

22

|

14

|

6

|

0.06

|

KM27

|

MB 27

|

|

M140x2

|

165

|

155

|

22

|

12

|

5

|

0.06

|

KML28

|

MBL 28

|

|

M140x2

|

180

|

160

|

22

|

14

|

6

|

0.06

|

KM28

|

MB 28

|

|

M145x2

|

190

|

171

|

24

|

14

|

6

|

0.06

|

KM29

|

MB 29

|

|

M150x2

|

180

|

170

|

24

|

14

|

5

|

0.06

|

KML30

|

MBL 30

|

|

M150x2

|

195

|

171

|

24

|

14

|

6

|

0.06

|

KM30

|

MB 30

|

|

M155x3

|

200

|

182

|

25

|

16

|

7

|

0.06

|

KM31

|

MB 31

|

|

M160x3

|

190

|

180

|

25

|

14

|

5

|

0.06

|

KML32

|

MBL 32

|

|

M160x3

|

210

|

182

|

25

|

16

|

7

|

0.06

|

KM32

|

MB 32

|

|

M165x3

|

210

|

193

|

26

|

16

|

7

|

0.06

|

KM33

|

MB 33

|

|

M170x3

|

200

|

190

|

26

|

16

|

5

|

0.06

|

KML34

|

MBL 34

|

|

M170x3

|

220

|

193

|

26

|

16

|

7

|

0.06

|

KM34

|

MB 34

|

|

M180x3

|

210

|

200

|

27

|

16

|

5

|

0.06

|

KML36

|

MB 36

|

|

M180x3

|

230

|

203

|

27

|

18

|

8

|

0.06

|

KM36

|

MB 36

|

|

M190x3

|

220

|

210

|

28

|

16

|

5

|

0.06

|

KML38

|

MBL 38

|

|

M190x3

|

240

|

214

|

28

|

18

|

8

|

0.06

|

KM38

|

MB 38

|

|

M200x3

|

240

|

220

|

29

|

18

|

8

|

0.06

|

KML40

|

MBL 40

|

|

M200x3

|

250

|

226

|

29

|

18

|

8

|

0.06

|

KM40

|

MB 40

|