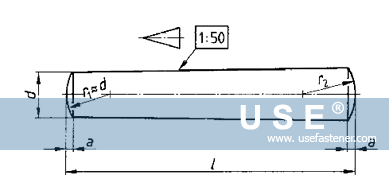

Type A (ground pins):Surface finish Ra=0.8um

Type B (turned pins):Surface finsh Ra=3.2um

|

d h(10)

|

a ≈

|

|

0.6

|

0.08

|

|

0.8

|

0.1

|

|

1

|

0.12

|

|

1.2

|

0.16

|

|

1.5

|

0.2

|

|

2

|

0.25

|

|

2.5

|

0.3

|

|

3

|

0.4

|

|

4

|

0.5

|

|

5

|

0.63

|

|

6

|

0.8

|

|

8

|

1

|

|

10

|

1.2

|

|

12

|

16

|

|

16

|

2

|

|

20

|

2.5

|

|

25

|

3

|

|

30

|

4

|

|

40

|

5

|

|

50

|

6.3

|